Cat6A Keystone Jack Connecting Hardware Component Test

The quality of each keystone jack, cable, and patch cord is an essential factor that can affect the transmission performance of the channel. So, we test each of our Category 6A Component Level Keystone Jacks individually (a component test) to ensure its quality and performance. Test reports are available for each Cat6A Component Level Keystone Jack (click onto the picture below to see the product 3J01-A01-00031). Each keystone jack and its test report have an ID number for easy identification. You can use the ID number on the keystone jack to find its test report and vice versa.

Traditional Keystone Jack Component Test

A traditional keystone jack component test typically takes 2 hours to test one single keystone jack. Why does it take 2 hours to do a keystone jack component test in a traditional way? The connecting hardware transmission test for the keystone jack must be performed in a mated state. So, we need to do several things to make sure that the performance of the test plug and test fixtures have very minimal effects on the result of the keystone jack component test and to ensure the accuracy of the test. It includes:

- Calibrate the test plug and the direct fixture (test plug performance measurement fixture) to ensure the integrity of the keystone jack component test.

- Maintain the characteristic stability of the entire test fixture to ensure its performance and quality.

- Carefully attach each pair of conductors to the test fixture and maintain the pair twist as much as possible.

- Measure the test plug NEXT loss for the 14 cases that are determined by combining the phase values and magnitude values.

- Use the network analyzer and computer software to calculate and draw the curves for the NEXT values and RL values on the test reports.

Automated Keystone Jack Component Test

Our self-designed automated component test for our Component Level Category 6A Keystone Jack (3J01-A01-00031) can be done in less than 1 minute, with our automated testing machine. Traditionally, the component test typically takes up to 2 hours to test a keystone jack. Our R&D team designed and developed a test machine to replace the traditional testing, streamlining the entire testing processes. Because of this immense improvement in the component test duration for each keystone jack, we can provide test reports for every one of our Component Level Cat6A Keystone Jacks.

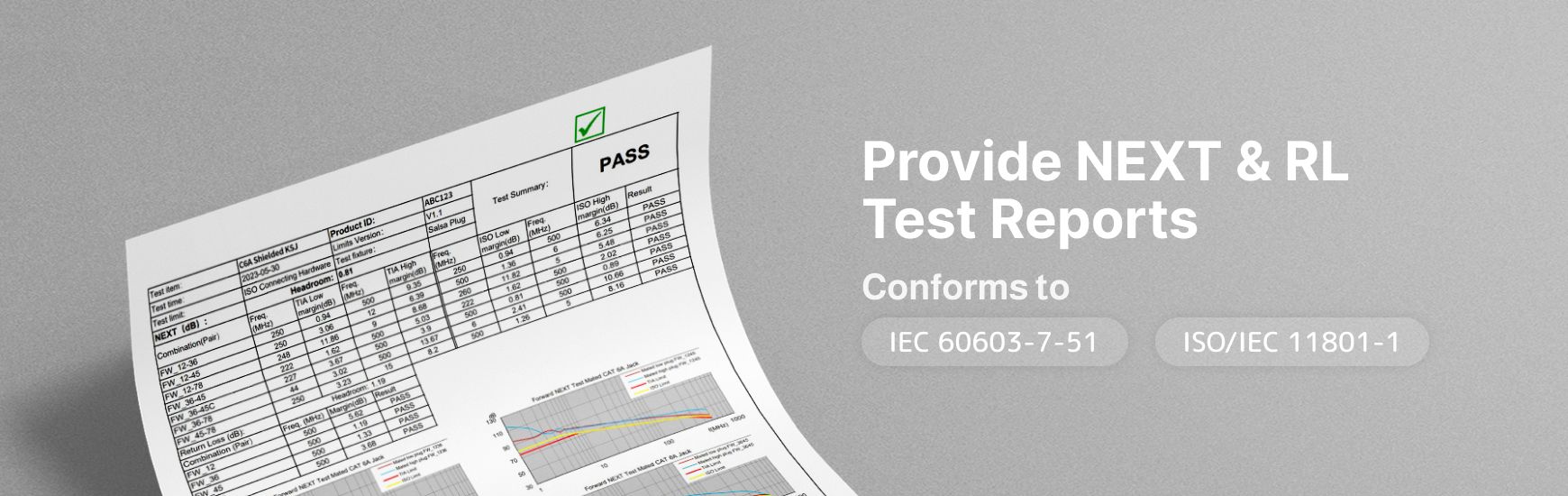

Test Reports for Our Component Level Category 6A RJ45 Keystone Jacks

We can provide near-end crosstalk (NEXT) and return loss (RL) test reports for each one of the Category 6A Component Level Keystone Jacks (click the picture below to see the product 3J01-A01-00031). We ensure that the Component Level Keystone Jacks alone meet ISO/IEC 11801-1 and IEC 60603-7-51 Category 6A performance. So, when you use our Component Level Keystone Jacks in a Category 6A channel, we reassure you that the Component Level Keystone Jacks will not downgrade the entire channel performance. The Category 6A Component Level Keystone Jack can support a true Category 6A bandwidth and a stable connection with a true Category 6A cable or patch cord that also meets the international standards mentioned above, providing predictable performance and having great flexibility to move, accommodate, or change. The properly tested RJ45 connecting hardware (keystone jack) will have minimal effects on cable performance and provide a true Category 6A transmission speed of 10 Gbps.

Unique ID on Every Keystone Jack and Corresponded Test Report

Each Category 6A Component Level Keystone Jack has an ID number. We use laser printers to print those unique numbers on every single one of our Component Level Cat6A Keystone Jacks (click the picture below to see the product 3J01-A01-00031). Each keystone jack is numbered, and its corresponding number appears on the test report. So, you can use the unique ID numbers on a random keystone jack and find its test report.

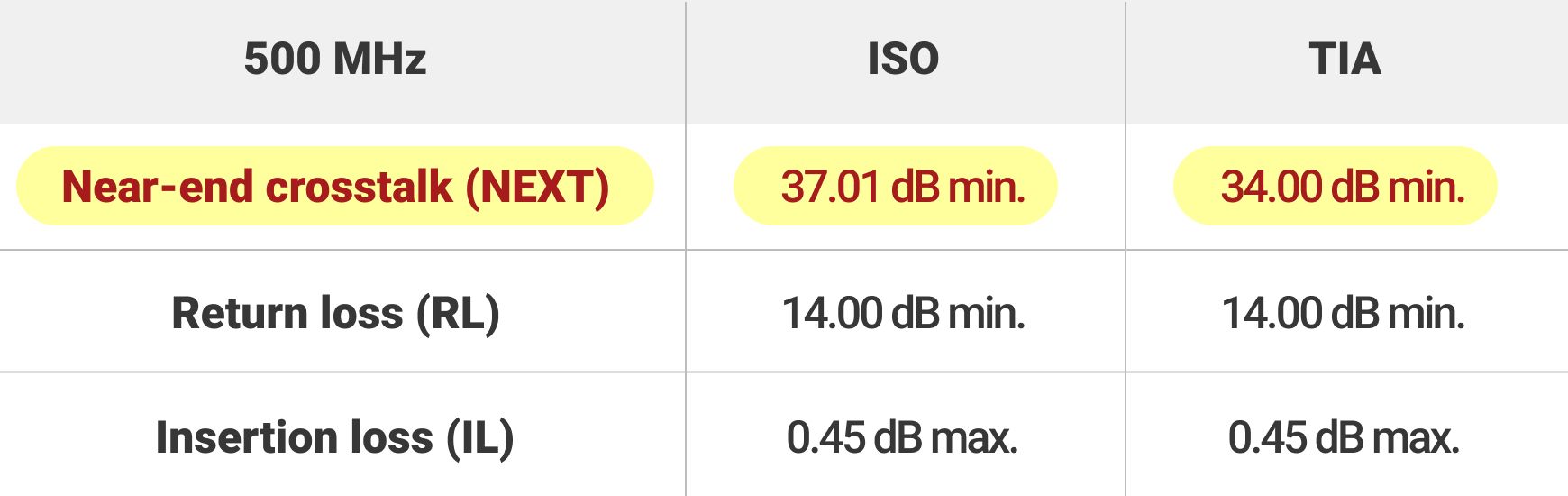

NEXT and Return Loss in the Test Report

NEXT (near-end crosstalk) and RL (return loss) are the two most important parameters in determining the performance of the keystone jacks. NEXT occurs when a signal on one wire or conductor in a twisted-pair cable interferes with signals on nearby wires. On the other hand, return loss measures the reflection of a signal back towards its source due to impedance mismatches in the cable or connectors. The NEXT and RL values of our Component Level Cat6A Keystone Jacks meet and exceed the transmission performance requirements for shielded 500 MHz Category 6A connecting hardware in IEC 60603-7-51. We provide the NEXT headroom and RL headroom in every component test report to ensure the quality of every keystone jack. Other parameters such as insertion loss are rather consistent if the keystone jacks are compliant with the mechanical and electrical characteristics in ISO 11801-1 and IEC 60603-7-1 for shielded Category 6A jacks.

Component Test Report: What is the NEXT Headroom and RL Headroom?

The headroom or margin of a NEXT value or RL value is how much the value of the connecting hardware exceeds the standard. Take the NEXT requirement of the ISO standard as an example, the minimum NEXT value of a 500 MHz connecting hardware is 37.01 dB, and a measurement is taken that shows a NEXT value of 37.98 dB. The NEXT “headroom” or “margin” in this case would be 0.97 dB, which is how much the measured NEXT value exceeds the ISO standard.

Difference in the Minimum NEXT and RL Values of the ANSI/TIA-568.2-D and ISO 11801-1

ISO 11801-1 has the strictest transmission performance requirements for the acceptable NEXT value for Category 6A 500 MHz connecting hardware as shown below. The NEXT value of the ISO and TIA standard for a 500 MHz Category 6A connecting hardware (keystone jack) are 37.01 dB and 34 dB. We use the ISO standard because its minimum requirement for the NEXT values is 3.01 dB higher than the minimum NEXT value for a 500 MHz connecting hardware in the TIA standard. Other parameters (return loss and insertion loss) are the same as the ANSI/TIA-568.2-D standard. So, each of the test reports shows the NEXT and RL values in both TIA and ISO standards to ensure the quality of each keystone jack.

- Related Products

Cat.6A STP Component Level Toolless Keystone Jack

The component level 4PPoE keystone jack has an ID number printed on it. A component test report...

Details Add to ListCat.6A S/FTP 26 AWG Patch Cord

Our Cat6A S/FTP Patch Cord is RoHS, UL, ETL, and FORCE compliant, guaranteeing reliable performance....

Details Add to List1U 24 Port FTP RJ45 Blank Panel

RJ45 Empty Panels 1U 24port FTP are available to snap in by Cat.5e and cat.6 and Cat.6a keystone...

Details Add to List- Tool Recommendations

Crimping Plier for RJ45 Toolless Plugs and Keystone Jacks

The unique crimping tool is simple and fast to work with Toolless plugs and jacks. The front...

Details Add to ListRJ45 Multi-Function Cable Tool

RJ45 cable stripper for RJ45 patch cords DIY assembly has 2 main functions: stripping depth...

Details Add to List- Related FAQ

The sparking test (also called arcing test) assesses the connector's ability to handle electrical arcs which might occur when connecting or disconnecting under load. An electrical arc is a visible glow...

Read moreWe measure the PS ANEXT and PS AACR-F values of our Cat6A U/UTP solution using the Fluke DSX CableAnalyzer to assess alien crosstalk (AXT), which can degrade overall channel performance. The 6 around 1 test...

Read moreThe Modular Plug Terminated Link (MPTL) is a new “direct connect” link model where a horizontal cable is terminated and directly attached to a modular plug or a tool-free field termination plug. MPTL...

Read more