Automated Production

Innovative Structured Cabling Solutions Manufacturing

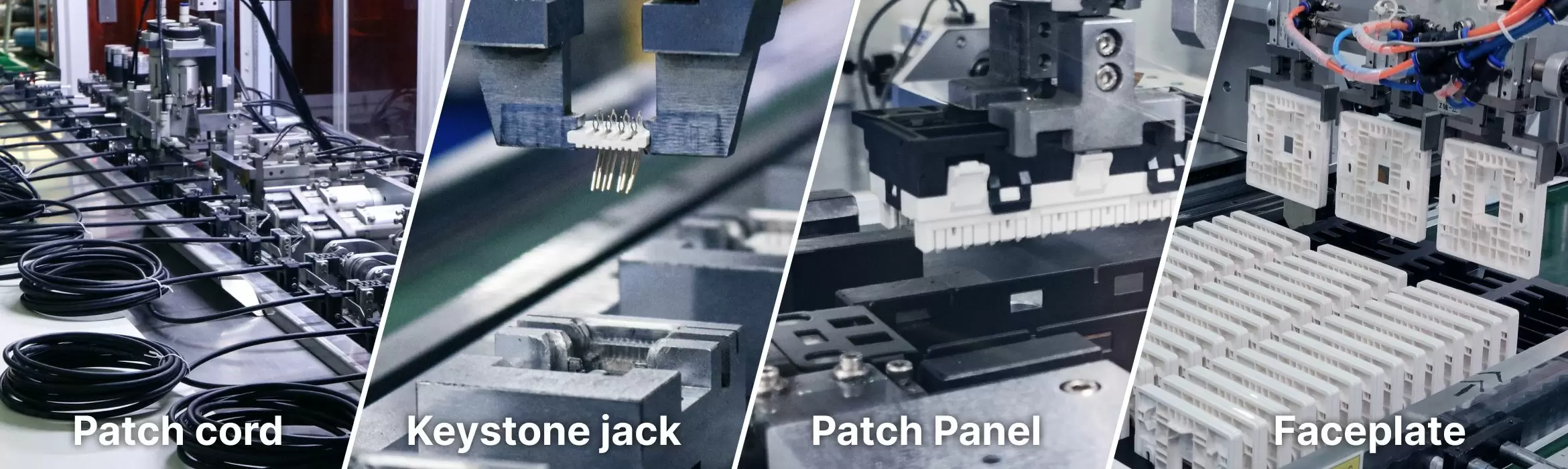

We incorporate automation and digitalization into the manufacturing of structured cabling solutions. Digitization contributes to more accurate lead times, and automation contributes to quicker lead times. Digitization in manufacturing provides real-time production status and production scheduling optimization. Automated manufacturing processes ensure precise and consistent assembly, resulting in high-quality patch cords, keystone jacks, patch panels, and faceplates with minimal defects. This reliability translates to excellent product performance and customer satisfaction.

Automation in Manufacturing RJ45 Copper Cabling Solutions

The manufacturing processes of our RJ45 copper cabling products have undergone many upgrades to streamline the entire processes and to achieve 100% automation or semi-automation. Automated machines work faster and more efficiently than human labor, which often leads to shorter lead times, allowing us to finish orders more quickly.

- Patch cord manufacturing automation

- Keystone jack manufacturing automation

- Patch panel manufacturing automation

- Faceplate manufacturing automation

Digitization in Manufacturing Structured Cabling Solutions

We provide a complete production line with consistent quality control, short turnaround time, and sufficient capacity for our products. Back in 2014, we launched the ARROW Machine Track System (MES Production Monitoring System) in our China Ningbo factory, bringing plant management to a higher level. It tracks all aspects of the production and automatically updates manufacturing schedule details. The result of this embedded solution is improved machine management, efficiency, visibility and productivity.

- Production scheduling optimization: stamping, gold plating, injection molding, and insertion.

- Real-time daily production capability

- Work-in-process inventory turnover rate

- Raw material prices

- Photovoltaic power generation status

- Employee attendance rate

- Equipment utility rate