Helping a Fiber Manufacturer Launch UL-Approved Copper Products

A Middle Eastern fiber manufacturer partnered with us to launch their new copper product line using UL and ETL certified Cat6A and Cat6 solutions. We conducted full in-house pretesting to ensure compliance with UL 1863, ISO 11801-1, and ANSI/TIA 568.2-D standards before third-party lab submission. From custom packaging design and logo printing to brochure content and rapid production, we delivered OEM/ODM solutions that matched their brand identity and exhibition needs—on time and with certified quality.

UL and ETL Certified Product Pretesting for a Fiber Manufacturer

Seeking UL and ETL compliant products to expand their copper product lines, the Middle Eastern fiber manufacturer chose to partner with us because our products are UL and ETL certified. However, the fiber manufacturer needed to send those products to a third-party laboratory by themselves. With our own in-house testing laboratories and abundant experience of certification submission, we pretested the products in house to further ensure that they are compliant with UL 1863 standards (pull tests, crush tests, flex tests, and flame tests), as well as ISO 11801-1 and ANSI/TIA 568.2-D standards (return loss limit, insertion loss limit, NEXT loss limit, channel test, and crosstalk test). These pretests ensured that our products had a better chance of passing third-party testing.

Satisfactory OEM/ ODM Packaging and Brand CIS Support

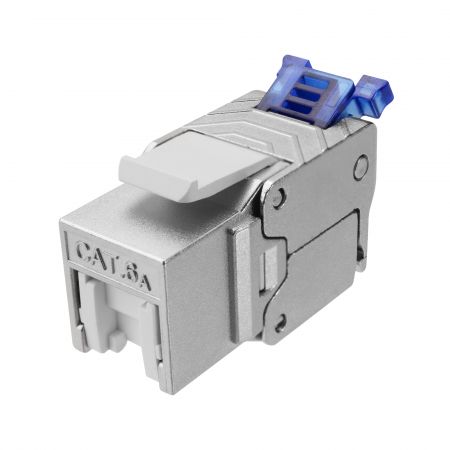

The fiber manufacturer needed Cat6A S/FTP and Cat6 U/UTP solutions and custom logo packaging including patch cord bags, keystone jack boxes, panel boxes, and export cartons. We tailored the packaging colors to their preference and printed the certificate logos they needed on the packaging and labels. We also provided product information to help them make their new marketing brochure. For their brand enhancement and visual appeal at exhibitions, the fiber manufacturer launched their new copper product lines through their new marketing brochures and concise videos to customers. They also showcased the OEM and ODM patch cords, keystone jacks, and empty panels with logo paper packaging for live hands-on demonstrations.

High-Quality and Efficient Production with Professional RD

Once we confirmed the fiber company's logo design, logo size, quantity of products per box, and paper packaging preference, we were able to satisfy their requested project timeline. Our RD team, automated machines, and professional technicians enabled us to deliver their custom Cat6A S/FTP and Cat6 U/UTP solutions by sea and air within 2-4 weeks, helping them complete their project within 4-5 weeks. We were able to meet all of the customer's requirements including UL and ETL certification, customized products/ packaging, and fast lead time.

Purchasing Process With Professional and Rapid Service

Our purchasing process, from inquiry to delivery, ensures expertise and fast service. We start with figuring out what the client needs and walk them through the ordering process (quotations, OEM/ODM needs, PO, PI, and payment). Whether it's standard packaging or customization, our streamlined purchasing and mass production procedures guarantee fast lead time and satisfactory service.

- Related Products

-

Cat.6A STP 180 Degree Toolless Keystone Jack

CAT6A shielded 4PPoE keystone jack is FORCE certified, and the RJ45 keystone jack is compliant with Category 6A Connecting Hardware performance. It is compact...

Details Add to ListCat.6A STP 180 Degree Toolless Keystone Jack With Cable Clamp

FORCE certified 4PPoE keystone jack is space-saving and compact for limited space. The Toolless RJ45 jack with a cable clamp delivers electricity up to 90 watts...

Details Add to List1U 24 Port FTP RJ45 Blank Panel

The RJ45 1U 24port FTP empty patch panels are available to snap in by Cat.5e and cat.6 and Cat.6A keystone jacks or couplers. There are label and inlaid...

Details Add to ListCat.6 UTP 180 Degree 1U 24 Port Patch Panel 110 and Krone Type

The Cat6 1U 24-Port 180° RJ45 Patch Panel complies with ANSI/TIA-568.2-D, UL, and RoHS standards, supporting 10GBASE-T performance. With 110/Krone termination,...

Details Add to ListCat.6A S/FTP 26 AWG Patch Cord

Our Cat6A S/FTP Patch Cord is RoHS, UL, ETL, and FORCE compliant, guaranteeing reliable performance. This Cat6A patch cord 100% passes Fluke component...

Details Add to List - Related FAQ

-

If you’re considering our AJ83 Cat6A/Cat6 Shielded Toolless Keystone Jack, this FAQ provides quick answers to help with your projects. You’ll find details on performance, compliance standards, and OEM/ODM...

Read moreThe quality of each keystone jack, cable, and patch cord is an essential factor that can affect the transmission performance of the channel. So, we test each of our Category 6A Component Level Keystone...

Read moreWe measure the PS ANEXT and PS AACR-F values of our Cat6A U/UTP solution using the Fluke DSX CableAnalyzer to assess alien crosstalk (AXT), which can degrade overall channel performance. The 6 around 1 test...

Read more- Files Download