Production Process

RJ45 Connector and Patch Cord Manufacturing Factory in Ningbo, China

Excellence Wire Ind. Co., Ltd. is a topnotch RJ45 cable and connector manufacturer based in Taiwan. Our manufacturing plant is located in Ningbo, China. We have a variety of RJ45 related products (e.g. patch cords, plugs, keystone jacks, patch panels, blank panels, wiring raceway duct, faceplates, surface mount boxes, IP68 waterproof solutions, inline couplers, and RJ45 tools). From Cat. 5e to Cat. 8, we have a complete line of RJ45 items that satisfy and exceed the international standards.

RJ45 Ethernet Cable Manufacturing Process

RJ45 Cable Assembly

With a total of 14 RJ45 patch cord production lines, we have the ability to mass produce 2 types of patch cables: pre-assembled and molded. We have 45 crimping machines and a professional mold workshop that can quickly produce a wide variety of patch cables within a short time. In the meantime, quality is everything to us. From human visual inspection to computer/machine-aided detection, assessments take place before and after production in effort to reduce the defect rate to the absolute minimum.

High Quality 8P8C Ethernet Cables

For the production of ethernet patch cables, we also evaluate critical parameters such as the near-end crosstalk (NEXT) and the return loss (RL) with Fluke DSX-8000 to ensure quality stability and excellence. After all of the assessments are done, the cables will be packed and shipped out to our customers from across the world.

RJ45 8P8C Connector Manufacturing Process

Stamping (monthly production capacity: 20M pcs)

The stamping machine takes a piece of phosphor bronze and transforms it into 2 strings of contact pins that are used to make 8P8C internet modular plugs. Each machine produces 4 strings at the same time and rolls the 4 strings into a spool.

Gold Plating (monthly production capacity: 20M pcs)

The gold plating machine electroplates a layer of gold on the surface over the phosphor bronze 8P8C contact pins. The thickness of the gold plating can be customized from gold flash to 50 micro inches.

Injection Molding (monthly production capacity: 50M pcs)

The injection molding machine mass manufactures the clear and durable polycarbonate plastic connector housings.

Initial Quality Control (AQL= 0.65)

The acceptance quality limit (AQL) in the initial quality control (IQC) of the entire manufacturing production process is 0.65%. In other words, we have no more than 0.65% defective items in the whole order quantity. Thus, the materials have undergone strict quality prior to production.

Riveting Machine for RJ45 8P8C UTP and STP Modular Plugs

The machine makes UTP and STP ethernet modular connectors simultaneously and efficiently. It automatically joins the polycarbonate (PC) housings and the zinc-alloy housings together by squeezimg with force in a downward motion.

Pin Insertion Machine (monthly production capacity: 30M pcs)

Each with the automated optical inspection (AOI), the pin insertion machine inserts the gold plated contact pins into a plug housing, combining the materials together to make a complete RJ45 male ethernet connector.

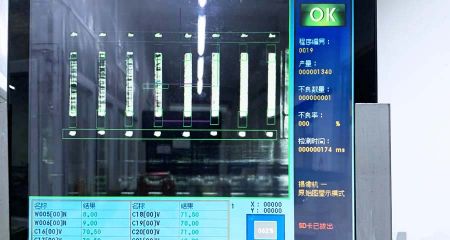

Automated Optical Inspection (AOI)

Each AOI has a camera that automatically scans the device under test for defects. Not only are the materials inspected before production, the finished products also follow the international standards and our stringent computer-assisted examination.

Automated Packaging (10, 20, 50 pcs/bag)

We self-develop the automated packaging machines to pack our products in smaller packages. Other than the large packages, we offer a greater degree of flexibility and diversity in packages, so we are able to satisfy the various demands from our customers all around the world.

Semi-Automated Sealing Machine

After connectors are packed in bags, the sealing machine further secures the connectors in the individual packages. It also increases production efficiency and improves the lead time on an order.

RJ45 Connector Production Process

The video desmonstrates the machines that we have been using while manufacturing the connectors and the functionality of each machine. Excellence Wire has a team of experienced and trained technicians who operate on the computers and machines to maintain efficinecy in manufacturing and ensure the quality of our products.

- Videos