Quality Assurance & Testing

Quality Assurance And Quality Control Testing Procedures Of RJ45 Plugs And Patch Cords

Excellence Wire ensures the quality of our products like patch cords and modular plugs, and we have our own R&D center that is well equipped to run routine tests, having the products certified by international standards, including ISO, REACH, and RoHS. From raw materials to final products, we conduct a variety of testing, as listed below. The test reports are available upon request. We stand behind our products and hold responsibility for the quality of patch cords and modular plugs.

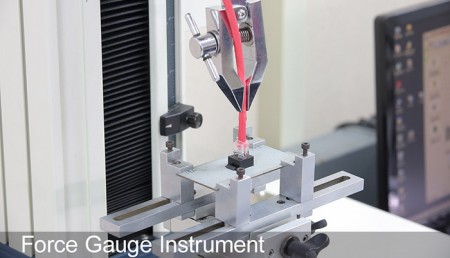

Tensile Strength Test (Pull Test) For RJ45 Patch Cords

The test is critical for selecting appropriate materials during research and development. The pull tester determines the maximum stress that a patch cord can withstand and verifies the minimum strength and elongation requirements to break the cable. We use a common testing method known as “Pull and Break” by directly pulling the wire joint until destruction. EXW patch cables can sustain pulling force up to at least 20 lbf (9.1 kgf) on average without being damaged.

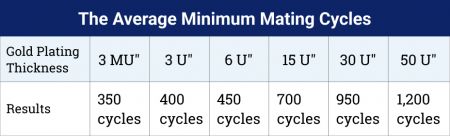

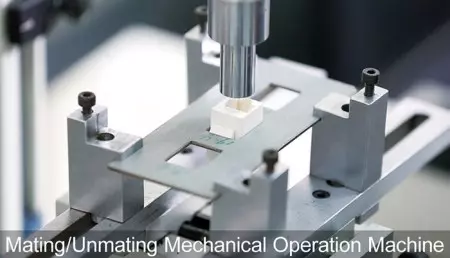

Insertion And Withdrawal Test For 8P8C Modular Plugs

We measure the insertion and withdrawal cycles of a patch cable at a constant speed of push-and-pull by a motorized test machine. This is done over multiple cycles to verify that our 50 microinch gold plated connectors exceed the international standard (750 cycles) and can be inserted at a minimum of 1,200 times, showing the superior durability of our patch cables.

Initial Quality Control of RJ45 Ethernet Cable Manufacturing And Assembly

We have strict IQC testing protocols of Ethernet cables and patch cords. The video will quickly walk you through the types of testing that we do before production. The comprehensive testing procedures include cable dimensional testing, measurement of insulation thickness, patch cord termination testing, and color inspection. We also have many additional testing. We are able to ensure quality and come up with inventive solutions to common issues that your type of project may have.

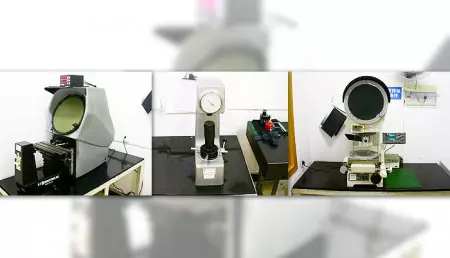

In-Process Quality Control of 8P8C Ethernet Patch Cord Assembly

The stringent IPQC of Ethernet patch cords is the final quality control (FQC) of RJ45 Ethernet connectors. From exterior inspection to functionality testing, the procedure includes plug housing hole diameter inspection, dimensional inspection, visual inspection, height inspection of retaining latch, bend testing of retaining latch, and connector pin height measurement. During visual inspection of modular plugs, we ensure that every plug housing has no black specks, flow lines, sink marks, vacuum voids, scratches, flashes, warping, and discoloration. In each bend testing, a retaining latch is bent at least 20 times to guarantee durability.

RJ45 Ethernet Plug Plating Thickness Measurement

We have a professional electroplating workshop to make different gold plating thicknesses of 8P8C plugs. The thickness of the gold coating is an essential factor in determining the functionality, appearance, and cost of a final product. Through the X-ray fluorescence (XRF) spectrometer, we can guarantee that our modular plugs meet the specified gold plating thickness required by our clients. The XRF analyzer is a very clean test method because it requires no chemicals. The plating thickness measurement can be done quickly with this non-destructive instrument.

RJ45 Plug Corrosion Resistance: Salt Spray Testing And Nitric Acid Testing

We offer 2 kinds of testing to assess corrosion resistance of the gold coating and the substrate materials: (1) salt spray testing for plug contact pins and gold wires and (2) nitric acid testing for gold wires. The contact pins are used in modular plugs, and the gold wires are component parts of keystone jacks. Both of the testing are common accelerated corrosion test methods. The samples under test are exposed to a highly corrosive environment in a closed cabinet over an extended period of time. The duration of the test is positively related to the plating thickness of RJ45 plugs.

- Videos

-

Tensile Strength Testing (Pull Test)

Insertion and Withdrawal Test (RJ45 Ethernet Connectors)

Initial Quality Control (RJ45 Patch Cords)

In Process Quality Control (RJ45 Patch Cords)

Plating Thickness Measurement (Contact Pins and Gold Wires)

Salt Spray Testing and Nitric Acid Testing (Corrosion Resistance Assessments)

- Photos

- Files Download

-